How to apply underfill adhesive glue dispensing to the bottom of chips on a PCB board?

Underfilling chips on PCB boards is a precision process primarily used for chips with ball grid arrays on their undersides, such as BGAs (Ball Grid

We believe Customer First from the first day of the business (this is the reason we name ourselves as the Second Intelligent.

We’ve focus on providing over 20 years in adhesive glue, materials dispensing and potting solutions.

Second Intelligent provides adhesive glue dispensing machines with quality and durable structures. We believe reliable machines and good solutions will gain us reputation and many repeating businesses in the industry globally.

Second Intelligent’s Precison Fluid Dispensing For Versatile Industrial Applications With Accurate Control.

Second Intelligent was established in 2006 with base in Shenzhen and is recognized as China’s leading manufacturer of providing solutions to fluid dispensing challenges, services customers across various industrial sectors with unparalleled technical expertise.

For more than 20 years, Second Intelligent has played an important role in the research, development, manufacturing, pre-sales and after-sales services of fluid dispensing, potting and coating solutions. With 40,000 square meters of production lines and more than 700 professional employees, its products have been exported to over 52 countries and regions around the world, including the United States, Canada, Vietnam, Thailand, Malaysia, Australia, Germany, France, England, Israel, etc, serving more than 5,000 well-known customers.

Additionally, as a research and development-oriented company, Second Intelligent has a dedicated R&D team with 200 engineers, whose aim is to assist its customers by providing them with tailor-made, value-added and environmentally-friendly solutions. Second Intelligent has obtained more than 300 patents on core technologies and software products, and the products have completely independent intellectual property rights, and have obtained many certifications, such as ISO9001, ISO14001, CE, CCC, and so on.

Our high quality products, range from various types of automatic fluid dispensing, potting, two-component potting machines and coating machines with desktop, free-standing, in-line or cobot combined systems, are widely used in global electrical, electronics, home appliances, automobile, telecom, pharmaceutical, automotive electronics, semiconductor, aerospace, LED and more.

With its long-term commitment to excellence, Second Intelligent has always been striving for constant product development, high-quality products and superb services, and becoming a 100-year service brand in fluid dispensing industry.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Industry Experience

Factory Sizes

Certificate

Number of stuff

Fluid Application Whole Solution Provider

We are direct manufacturer.

Generally, we pack our goods with proper wooden box. However, if client has special requirment, we can customize.

Depends on terms and conditions, negotiable.

EXW, FOB,CIF…

Yes, we can produce according to the tested result. We can also product base on your design.

Yes, we will test 100% before delivery.

We keep good quality and competitive price to ensure our customers benefit. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

Dispensing machine is an automatic machine and equipment that specializes in controlling fluid and dripping, coating, and potting the liquid on the surface of the product or inside the product. The glue dispenser is mainly used for glue and paint in the product process.

Glue dispensers are generally suitable for small products or electronic components, which are more precise; the products of potting dispensers are generally larger.

As long as it is a fluid with a viscosity within a certain range, it can be operated. The glue generally used in the dispenser includes red glue, hot melt glue, silica gel, grease and so on.

Yes. Dual-fluid models with 1:0.8~1:1.2 mixing ratio control are available.

0.1mm diameter with ultra-fine nozzles (requires low-viscosity fluids).

CE, UL, ISO 9001, and RoHS compliance for global markets.

Yes. Dual-fluid models with 1:0.8~1:1.2 mixing ratio control are available.

3C electronics, EV batteries, LED packaging, solar panels, and biomedical devices.

Shenzhen and is recognized as China’s leading manufacturer of providing solutions to fluid dispensing challenges

We believe Customer First from the first day of the business (this is the reason we name ourselves as the Second Intelligent.

We’ve focus on providing over 20 years in adhesive glue, materials dispensing and potting solutions.

We have mature teams for pre-sales and after- sales service and supports.

We are able to provide total integrating adhesive automation solutions.

Do not hesitate to contact us for further information, thanks in advance for your support!

Underfilling chips on PCB boards is a precision process primarily used for chips with ball grid arrays on their undersides, such as BGAs (Ball Grid

Dispensing and coating processes are widely used in manufacturing, while plasma cleaning serves as a critical pre-treatment step, significantly enhancing their quality and reliability. Plasma cleaning creates an

As the core power device in power electronic equipment, the packaging reliability of IGBTs (Insulated Gate Bipolar Transistors) directly determines the lifespan and performance of

India’s industrial water purification market is experiencing explosive growth. The market size reached $$2.73 billion in 2025 and is projected to surge to$$4.35 billion by

Power batteries serve as the engine equivalent for gasoline vehicles and the primary power source for new energy vehicles. Power battery modules are assembled by

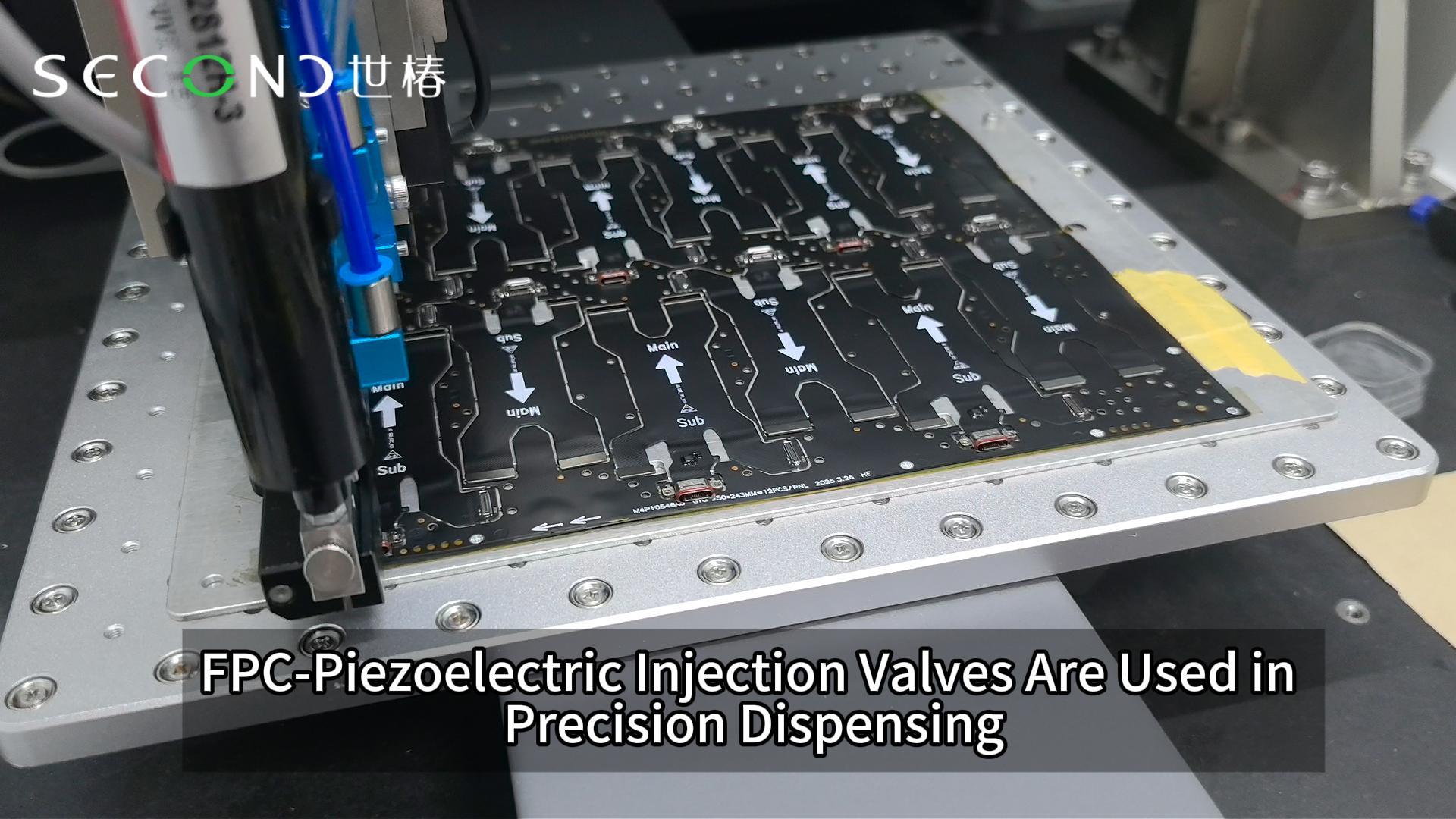

As electronics, medical devices, and advanced manufacturing continue to demand higher precision and consistency, piezoelectric injection valves have become a critical component in modern dispensing